Equipment and Apparatus

Conducting research and teaching activities is possible thanks to the equipment facilities of the Laboratory and the entire Faculty of Civil Engineering and Architecture. Below is a description of selected devices constituting the laboratory equipment.

WalterBai concrete and steel testing system

The device is equipped with three frames:

The machine works with extensometers used to test the modulus of elasticity of concrete and deformations during the tensile test of reinforcing bars, as well as a strain gauge bridge with the possibility of reading deformations at 8 measuring points.

Example application

Testing the modulus of elasticity of concrete using the Proteus program and an extensometer with two-sided measurement of deformation.

|

Dynamic axial-torsion system MTS model 319.25

Structures rarely experience only static loads and therefore knowledge of the material's fatigue properties is very important. The axial-torsion system meets all the accuracy requirements for this type of device by domestic and foreign standards (ISO, DIN or ASTM). |

|

Advantest 9 concrete and mortar testing system (manufactured by Controls)

The machine is equipped with three frames:

The system works with a strain gauge bridge with the ability to read deformations at 4 measuring points. Additional inserts enable testing the tensile strength of concrete elements, e.g. standard cylindrical or cube samples, or finished products in the form of paving stones.

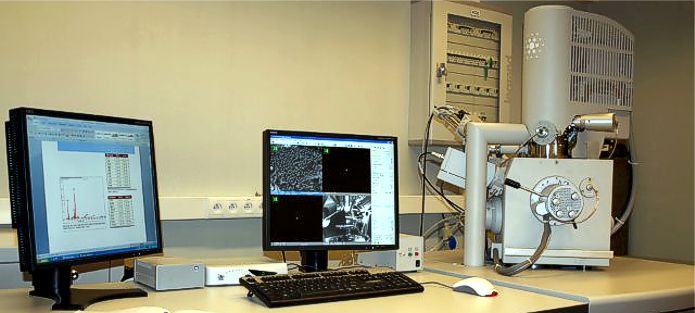

QUANTA FEG 250 scanning electron microscope

The laboratory has a scanning microscope QUANTA FEG 250 by FEI - SEM, in which the electron beam, focused on the surface of the tested sample into a spot with a very small diameter (up to 0.1 nm), sweeps a selected rectangular area of the surface with a scanning motion. The electrons of the beam penetrate the sample to a small depth, some undergo the so-called backscatter; most of them, however, remain in the sample, losing energy in various kinds of interactions, accompanied by the emission of secondary electrons, Auger electrons, X-rays, light and others. The use of dedicated detectors allows to obtain selected information about the tested material.

Example application

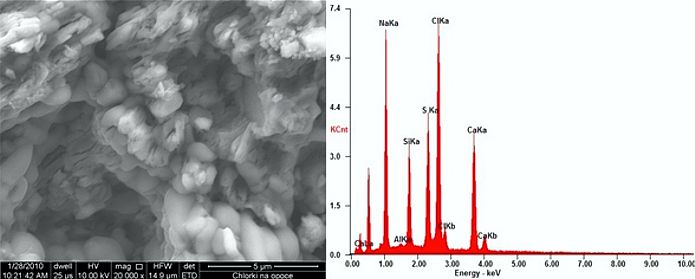

Chemical analysis on thebasis of the entire surface of the photo

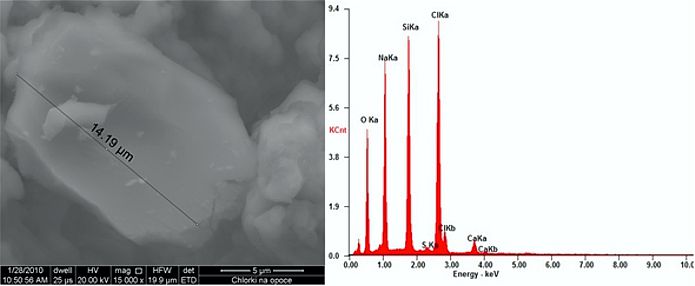

Chemical analysis of crystal composition - dimensioning

![]()

|

Instron impact tower The device is used to simulate puncture, dynamic compression, Charpi impact strength measurements, Izod impact strength measurements, and others. Selected operating parameters:

|

|

|

Example application |

|

|

Sample after testing at a speed of 1 m/s. |

|

![]()

|

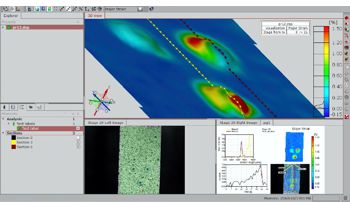

Aramis system Aramis is a system for non-contact 3D strain measurements. Analyzes, calculates and documents deformations. And the graphical presentation of the measurement results gives the possibility of a fuller understanding of the behavior of the tested object. Based on images taken with digital cameras, ARAMIS recognizes the surface structure of the measured object (each pixel in the image is assigned appropriate coordinates). After recording all the images, ARAMIS compares them and calculates displacements and strains. It is particularly useful for measuring three-dimensional deformations caused by static or dynamic loads. Most of the functions of the entire measurement system are controlled by the software, e.g. measurement, calculation, printing. |

|

|

System features:

|

|

|

Applications:

|

|

|

Charpy's Hammer The Charpy impact hammer enables the measurement of the energy needed to break the sample in a dynamic bending test and the impact strength, i.e. the ratio of the work needed to break the sample to the cross-sectional area of the sample at the fracture site. |

|

|

Universal hardness tester The hardness tester allows you to determine the hardness of materials according to Brinell, Rockwell and Vicers scales using standardized indenters - steel balls of various diameters, a diamond cone or a diamond pyramid. The measurement and loading of the sample is automatic, the reading of the result is electronic or using the attached precise measuring microscope. The reading accuracy is 0.1 degree. The hardness tester allows you to test the hardness of a wide range of materials, from wood and plastics to very hard ceramic composites. Hardness is a property of solids corresponding to resistance to concentrated forces. |

|

Projekt współfinansowany ze środków Unii Europejskiej w ramach Europejskiego Funduszu Społecznego, Program Operacyjny Wiedza Edukacja Rozwój 2014-2020 "PL2022 - Zintegrowany Program Rozwoju Politechniki Lubelskiej" POWR.03.05.00-00-Z036/17